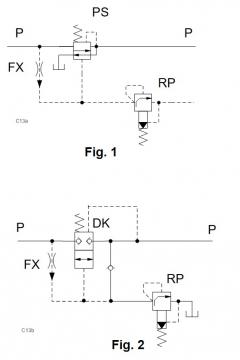

This example shows a direct-acting pressure-reducing/relieving main-stage element piloted with pressure created by an anti-shock relief valve. Fig.2 shows a normally closed balanced logic element as pressure-reducing valve.

- Pressure-reducing /relieving: PS*T

- Balanced logic element: DK*S

- Anti-shock relief: RP*T

- Flow control: FX*A

Benefits of this circuit arrangement

- Standard pressure-reducing/relieving valves (pilot-operated PP** and direct-acting PR**) are normally open valves that allow a pressure spike travelling through the valve when the supply pressure increases rapidly. Both circuits use normally closed elements. They open only after pilot pressure has built up between the pilot flow control and a pilot relief valve.

- Fig.1 uses a direct-acting spool-type reducing/relieving valve as a main stage. It gives a precise pressure control. The controlled pressure P is about 10 psi below the setting of the pilot valve RPET. Using a proportional valve RBAP instead of a RPET provides good control at very low pressures.

- Fig. 2 uses a normally closed balanced logic valve DK*S as a main stage. It offers greater pressure reducing stability when the downstream flow changes rapidly. A check valve between the pilot stage and P provides an optional additional relief function.