Pilot-operated, pressure reducing/relieving main stage with integral T-8A control cavity assembly

Symbols

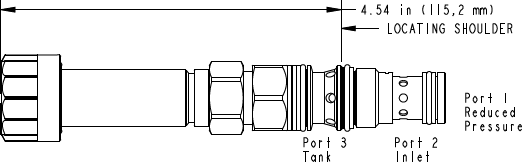

This valve is a 3-way, normally open modulating element that incorporates an integral pilot control cavity. The pilot control cavity will accept any T-8A pressure control cartridge. The valve reduces a high primary pressure at the inlet (port 2) to a constant reduced pressure at port 1, with a full flow relief function from port 1 to tank (port 3). The pilot cartridge's setting determines the difference in pressure between reduced pressure (port 1) and the tank (port 3).

- Pressure at port 3 is directly additive to the valve setting at a 1:1 ratio and should not exceed 3000 psi (210 bar).

- Maximum inlet pressure is determined by the bias spring. The D spring is tested with 2000 psi (140 bar) maximum differential pressure and the W spring is tested with 5000 psi (350 bar) maximum inlet pressure.

- NOTE: With the -8 control option, the main stage valve should first be installed to the correct torque value. The T-8A pilot control valve should then be installed into the main stage valve to its required torque value.

- The -8 control option allows the pilot control valve to be incorporated directly into the end of the relief cartridge via the T-8A cavity. These pilot control cartridges are sold separately and include electro-proportional, solenoid, air pilot, and hydraulic pilot operation. See Pilot Control Cartridges.

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- Full reverse flow from reduced pressure (port 1) to inlet (port 2) may cause the main spool to close. If reverse free flow is required in the circuit, consider adding a separate check valve to the circuit.

- Pilot operated valves exhibit very low dead-band transition between reducing and relieving modes.

- Pilot operated valves exhibit exceptionally flat pressure/flow characteristics, are very stable and have low hysteresis.

- All three-port pressure reducing and reducing/relieving cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size). When considering mounting configurations, it is sometimes recommended that a full capacity return line (port 3) be used with reducing/relieving cartridges.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-11A |

| Series | 1 |

| Capacity | 10 gpm40 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Control Pilot Flow | 7 - 10 in³/min.0,11 - 0,16 L/min. |

| Pilot Control Cavity | T-8AT-8A |

| Pilot Control Valve Installation Torque | 20 - 25 lbf ft27 - 33 Nm |

| Pilot Control Valve Hex Size | 7/8 in.22,2 mm |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Model Weight | .30 lb0,15 kg |

| Seal kit - Cartridge | Buna: 990011007 |

| Seal kit - Cartridge | EPDM: 990011014 |

| Seal kit - Cartridge | Polyurethane: 990011002 |

| Seal kit - Cartridge | Viton: 990011006 |

This 2-port, pilot-stage, direct-acting relief cartridge is an electro-proportionally controlled, pressure regulating valve. The proportional control allows for infinite, step-less adjustability within the selected pressure range. When the pressure at port 1 (inlet) is sufficient to overcome the solenoid forces, as determined by the analog input signal, the poppet lifts and allows flow from port 1 to port 2 (outlet). This pilot control cartridge utilizes the T-8A cavity so it can be used in conjunction with Sun's main stage, pressure control elements.

- Varying the analog input signal to the proportional solenoid provides a step-less control of pressure.

- This electro-proportional cartridge utilizes the Sun T-8A, 2-port cavity making it the ideal choice to use in conjunction with Sun's main stage cartridges. Separate pilot lines are eliminated and only one cavity needs to be machined to accommodate both the control and primary function. Note: All 2-port pilot stage control cartridges utilize the same cavity and are physically interchangeable. Functionality is the only consideration.

- All pressure ranges will drop to a setting of 0 with no analog input signal. The pressure ranges indicate the valve's area of acceptable performance.

- The L control (Manual Override - Adjustable) allows one to manually adjust the valve in case of an electrical failure. The L control also allows one to offset the pressure range. For instance, if an A range valve is mechanically offset to a setting of 1500 psi (105 bar), the new maximum will be 4500 psi (310 bar).

- The 'E' manual control assembly has a mechanical life expectancy of approximately 7,000 cycles.

- Damped construction provides stable operation over a wide range of operating conditions. Note: Models equipped with an 'M' control do not incorporate the dampening orifice in the solenoid armature.

- The momentary/twist override option "E" allows the operator to shift the valve by twisting the manual override clockwise 90 degrees.

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- Note: The main stage valve should first be installed to the correct torque value followed by the T-8A pilot control section into the main stage valve to its required torque value.

- For optimum performance, an amplifier with current sensing and adjustable dither should be used. Dither should be adjustable between 100 - 250 Hz.

- NOTE: There is no upper limit to the pressure setting when using the M control. The more force you exert on the manual override, the higher the resulting pressure.

- High pilot capacity allows for operation of larger size main stage elements.

- Capable of operating with pressures up to 5000 psi.

- Low leakage levels in the closed position. (Reseat occurs at 85% of cracking pressure.)

- Coils are interchangeable with Sun's other full flow, solenoid operated valves and can be mounted on the tube in either direction.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-8A |

| Series | P |

| Capacity | .25 gpm1 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Maximum Valve Leakage at Reseat | 1.5 in³/min.25 cc/min. |

| Manual Override Force Requirement | 10 lbs/1000 psi @ Port 166 N/100 bar @ Port 1 |

| Reseat | >85% of setting>85% of setting |

| Solenoid Tube Diameter | .75 in.19 mm |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 20 - 25 lbf ft27 - 33 Nm |

| Model Weight (with coil) | 1.00 lb0,45 kg |

| Seal kit - Cartridge | Buna: 990208007 |

| Seal kit - Cartridge | EPDM: 990008014 |

| Seal kit - Cartridge | Viton: 990208006 |

| Seal and nut kit - Coil | Viton: 990770006 |

- Compound cartridge (pilot and main stage) assembly information is provided for reference only. Cartridges must be ordered separately and assembled at point of use.

- Please verify cartridge clearance requirements when choosing a Sun manifold. Different valve controls and coils require different clearances.

- Pressure Relief and Regulating Cartridge Valve Technical Tips

- Pilot-Operated, Balanced Poppet Relief Valves

- Sun Expands Corrosion-Resistant Solutions

- Get the relief you need. Adjustable. Ventable. Blockable. FLeX-ible.

- Sun Offers Zinc-Nickel Plating for Corrosion Resistance

- Sun Cartridges with EPDM Seals

- 'Soft' Relief Eliminates Pressure Spikes

- Factory-tuned, optimized electro-hydraulics right out of the box

- Pilot-Operated, Balanced Poppet, Anti Shock Reliefs

- CavitySaver multi-function valves deliver single-cartridge solutions

- Sun Introduces 'Hybrid' Valves

- CANpoint XMD Configuration Software

- Tri-Grip Handknob Now Offered From Sun as a Standard Control Option

- QuickDesign with SmartConnect Offers Drag-and-Drop Schematic Tool

- Electro-Proportional Basics Explained

- Precise electro-proportional inverse relief valve

- CE/TÜV Certified Pressure Relief Valves

- Sun's New FLeX Series Solenoid Valves & Coils

- Proportional Amplifiers and Ancillary Products (2.06 MB)

- Manufacturing Sun Cartridge Cavities (522.27 KB)

- Solenoid Coils for Switching and Proportional Valves (975.2 KB)

- Reducing and Reducing/Relieving Valves (229.15 KB)

- Pressure Relief and Regulating Valves (655.91 KB)

- Cavity Information (S-171) and Tooling

- Electro-Hydraulic Terms and Definitions (2.94 MB)

- Cartridges: Materials of Construction

- Fluid Recommendations: Oil Viscosity, Cleanliness & Temperature

- Sun's Floating Style Screw-In Cartridge (1.06 MB)

- Units of Measure, Settings, and Conversions

- Performance Data

- Sun Model Code Explanation; 999-901-334 (343.9 KB)

- Pressure Equipment Directive 2014/68/EU