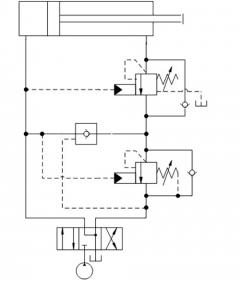

Cylinders can extend with pressure on both the piston side and rod end side. This is called a regeneration circuit. The reduced effective area (rod diameter) results in a higher extension speed at a reduced foce. A counterbalance valve can be used for a smooth transition from the regeneration mode of the cylinder to the standard mode when the rod side of the cylinder is diverted to tank. A vented counterbalance is required for additional load holding on the rod end side.

- Pilot-to-close check valve: CO*A-XEN

- Vented counterbalance valve: CW**, CA**

- Counterbalance valve: CB*A, CBEJ

Benefits of this circuit arrangement:

- For fast extension of the cylinder, the pilot-to-close CO*A valve allows flow from the rod side of the cylinder to the piston side of the cylinder. This flow is additive to the pump flow. A small directional valve is sufficient for the higher flow, as the high flow in regeneration mode does not pass through that valve.

- CB opens when the pilot pressure P times pilot ratio (usually 3) plus pressure P on the inlet to CB exceed the setting of the CB valve. A CBEA set at 4000 psi opens to tank at P = 1000 psi

- In regen mode, the additional counterbalance valve CW on the rod end side sees high back pressure. A vented counterbalance valve is required for load-holding to prevent unwanted cylinder extension.

For Sun technical support, contact Steve Weber.